AirForm

2023

Footwear Concept. Soft Robotics.

Individual Project

SuperGreen, Innovation Design Engineering (IC x RCA)

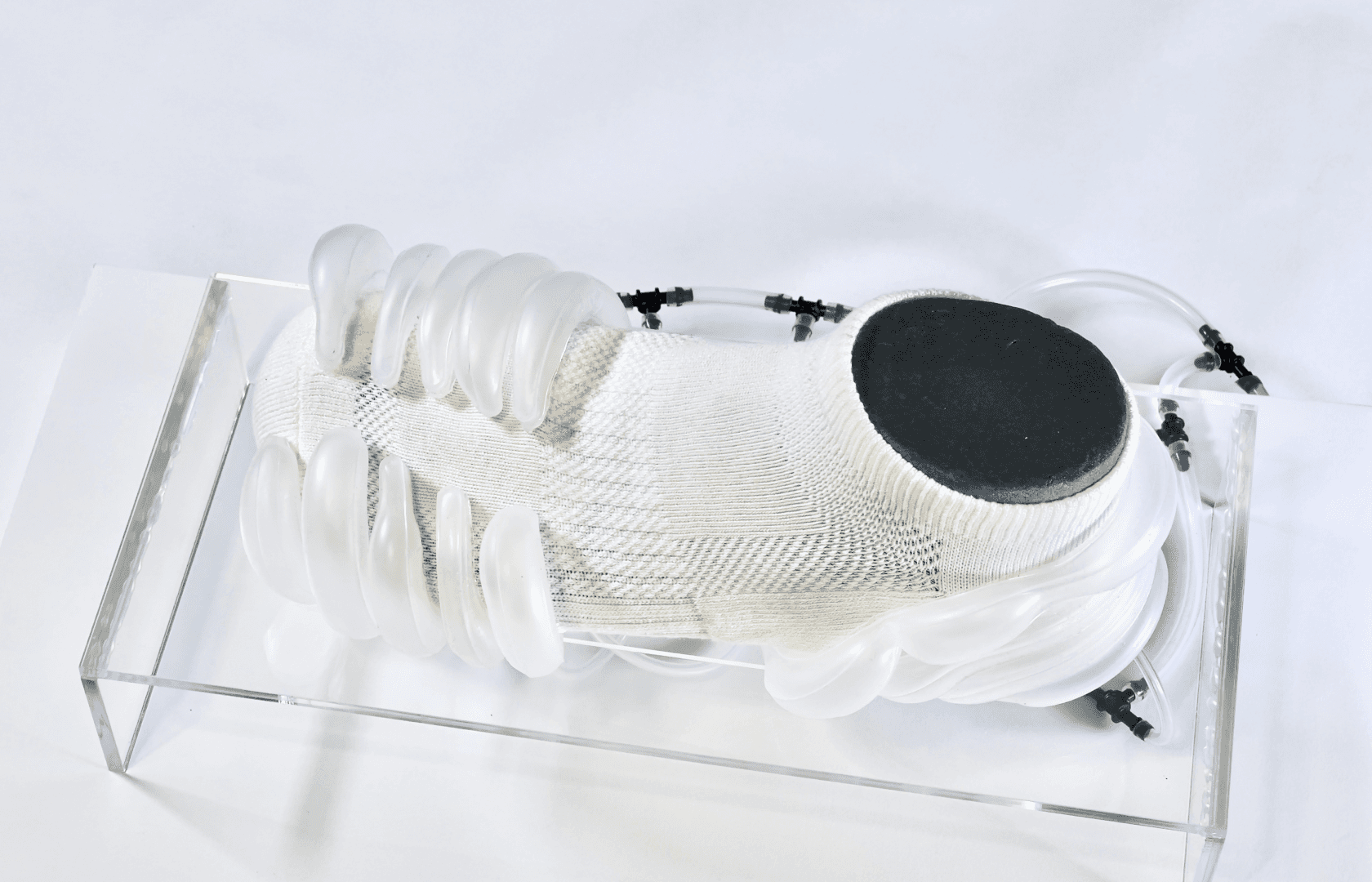

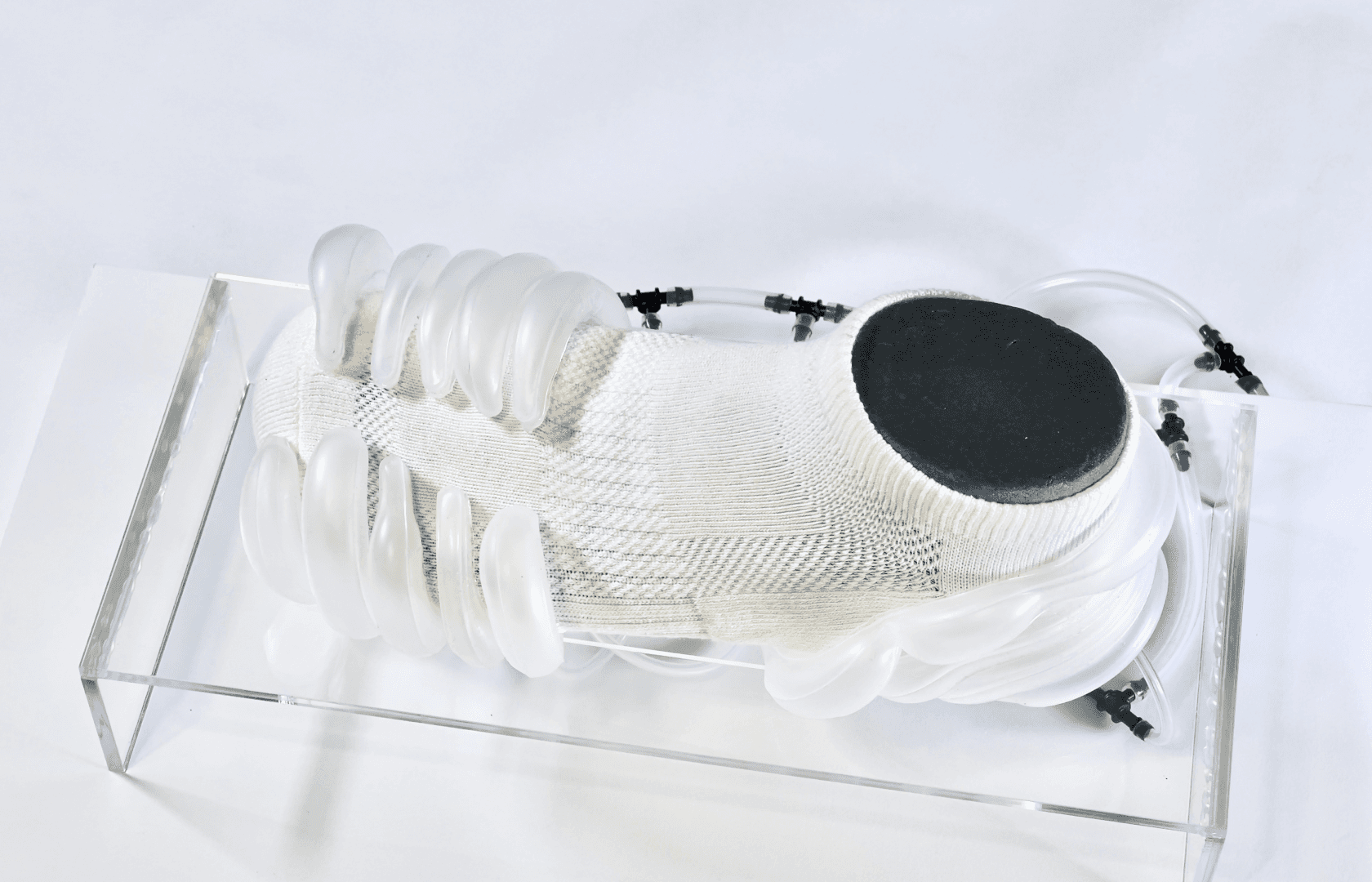

AirFORM aims to transform a single shoe into multiple styles through its form transformation ability, using an inflatable structure for adaptability. This reduces the need for multiple shoes, promoting sustainability. By activating specific air cushion units on the shoe’s surface, it inflates designated areas to achieve the desired shape for various shoe types.

Context

The majority of sneakers are made from plastics or similar materials, which generate significant carbon dioxide emissions. Typically, people wear different sports shoes for different activities, often storing those that are less frequently used. What if we could reduce our shoe collection and instead have one versatile shoe that adapts to various needs?

Concept

With the goal of transforming one shoe into multiple styles, I introduce AirForm, a footwear concept that uses air and inflatable mechanisms to create adaptive and regenerative structures. Equipped with individual cushion units connected to an air pump, the shoe’s form can be adjusted to any desired shape, allowing it to serve as various types of shoes.

Process

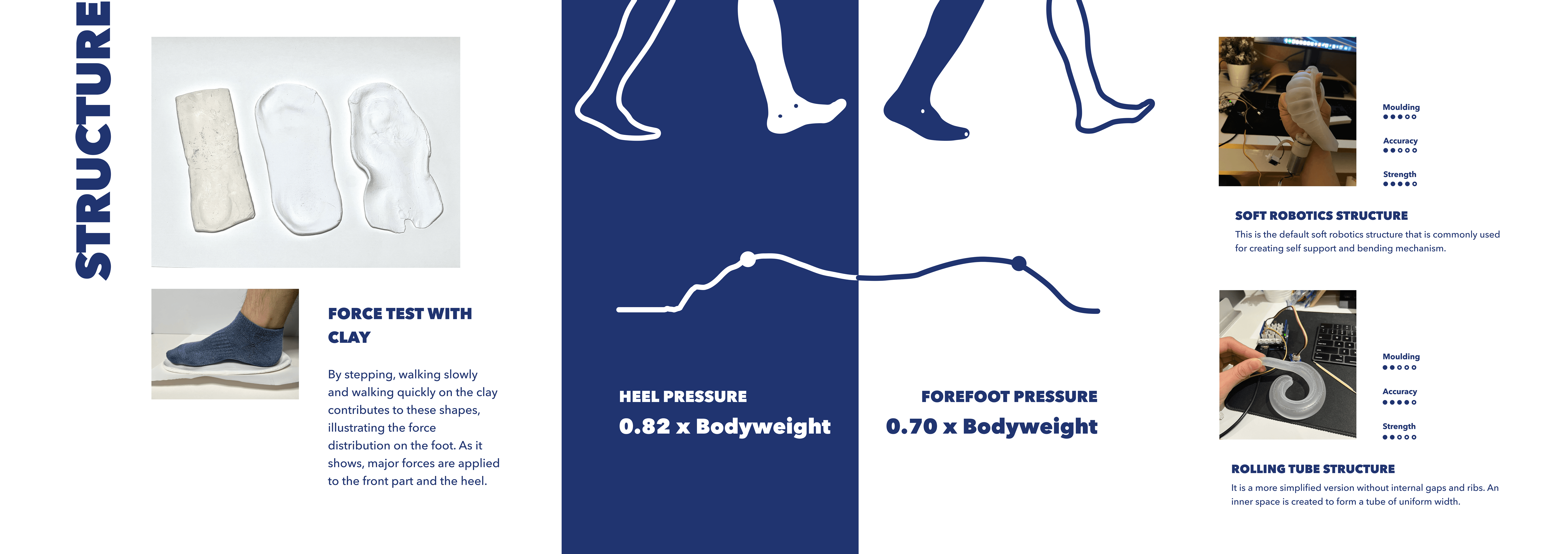

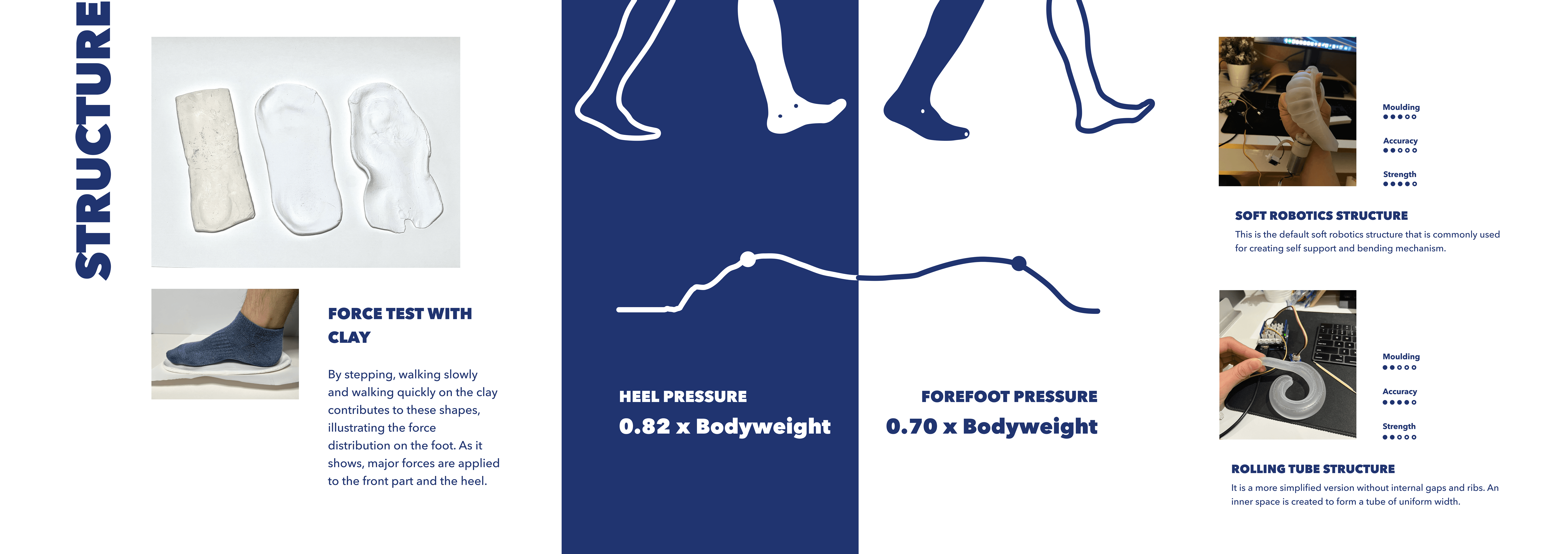

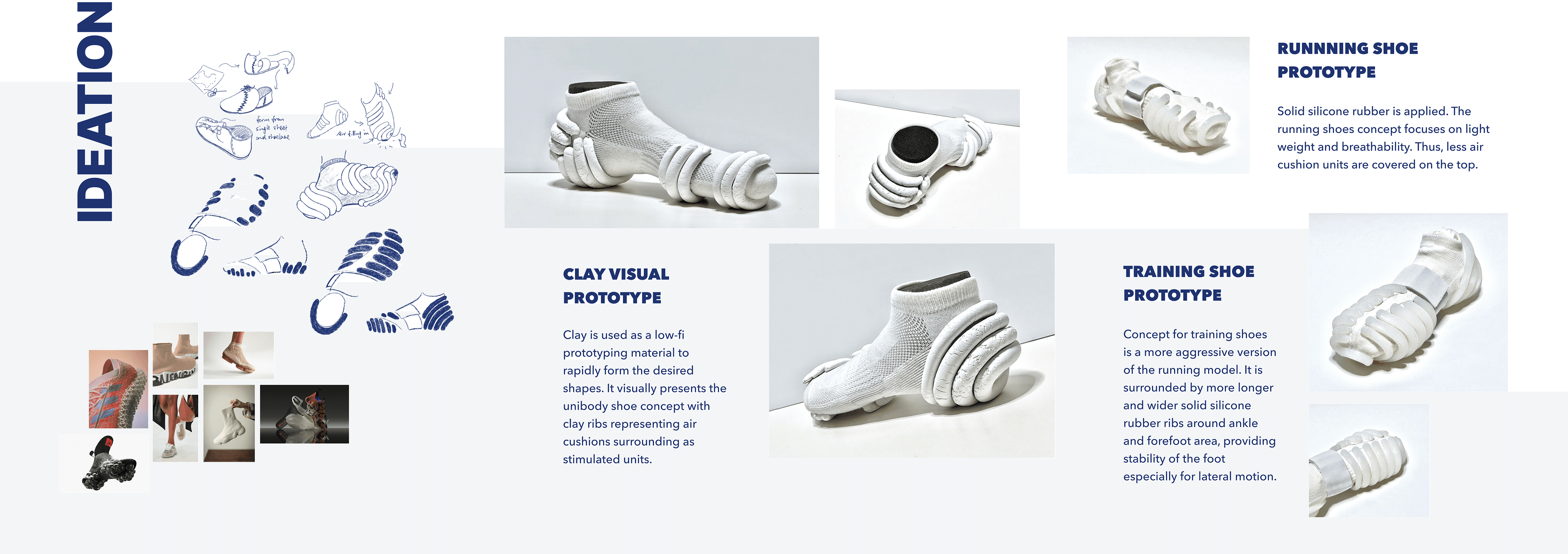

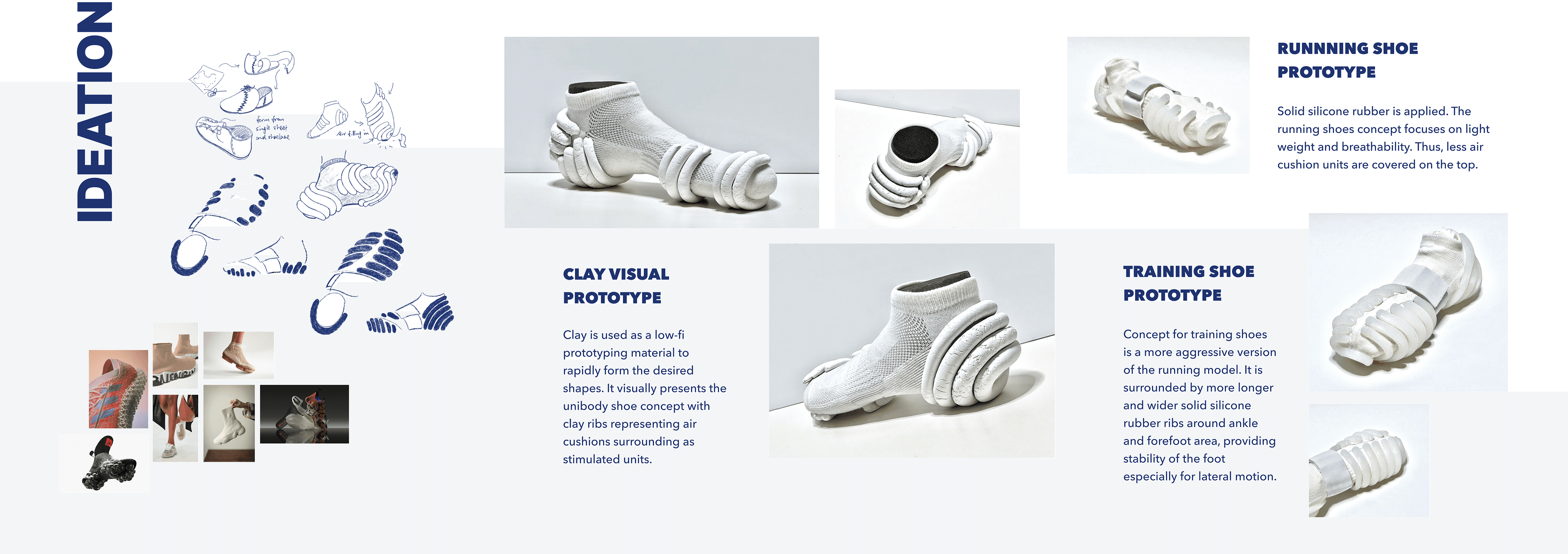

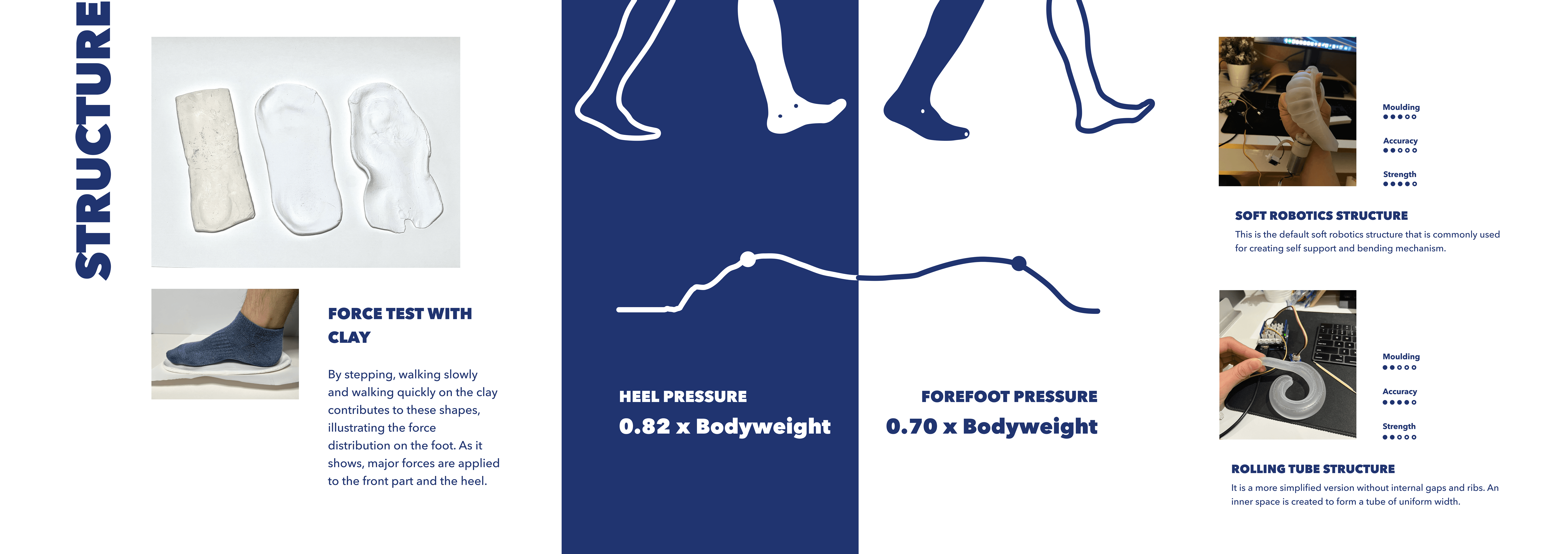

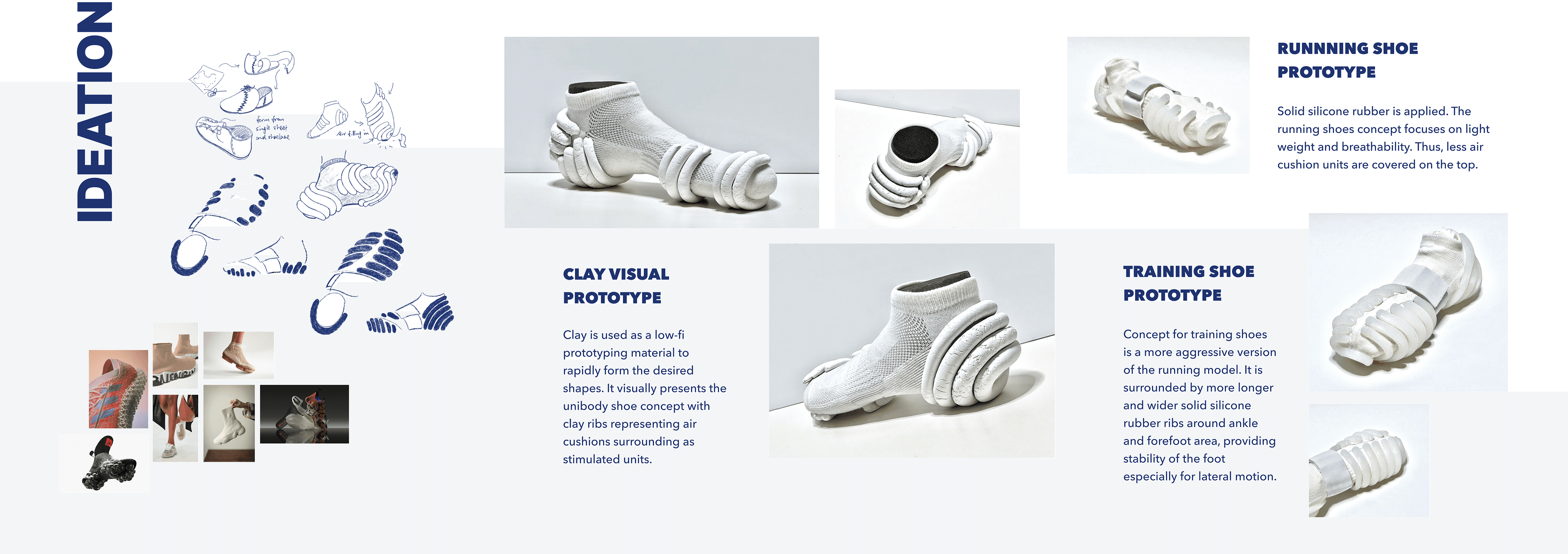

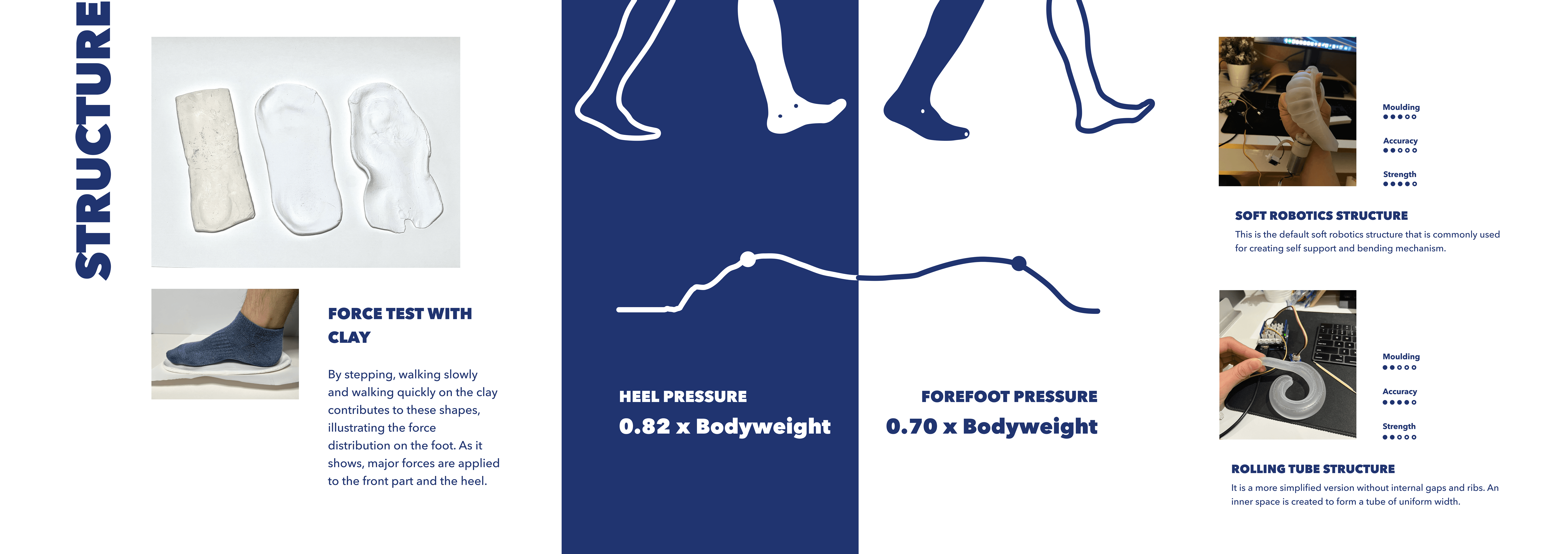

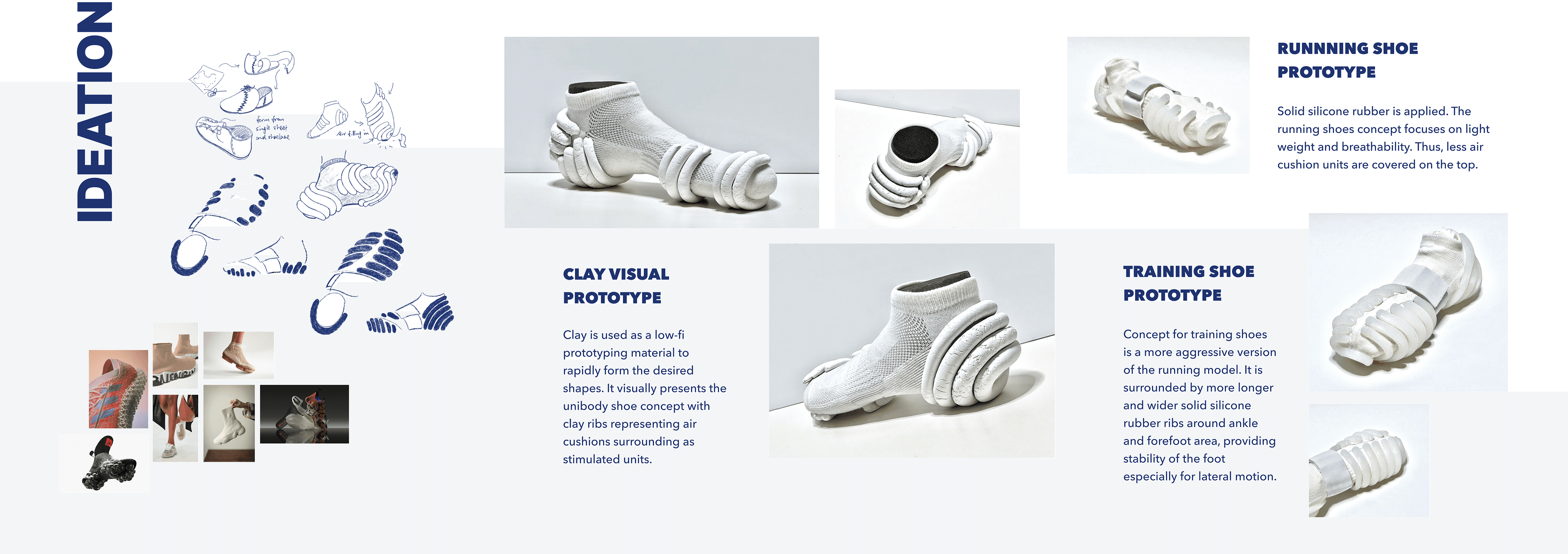

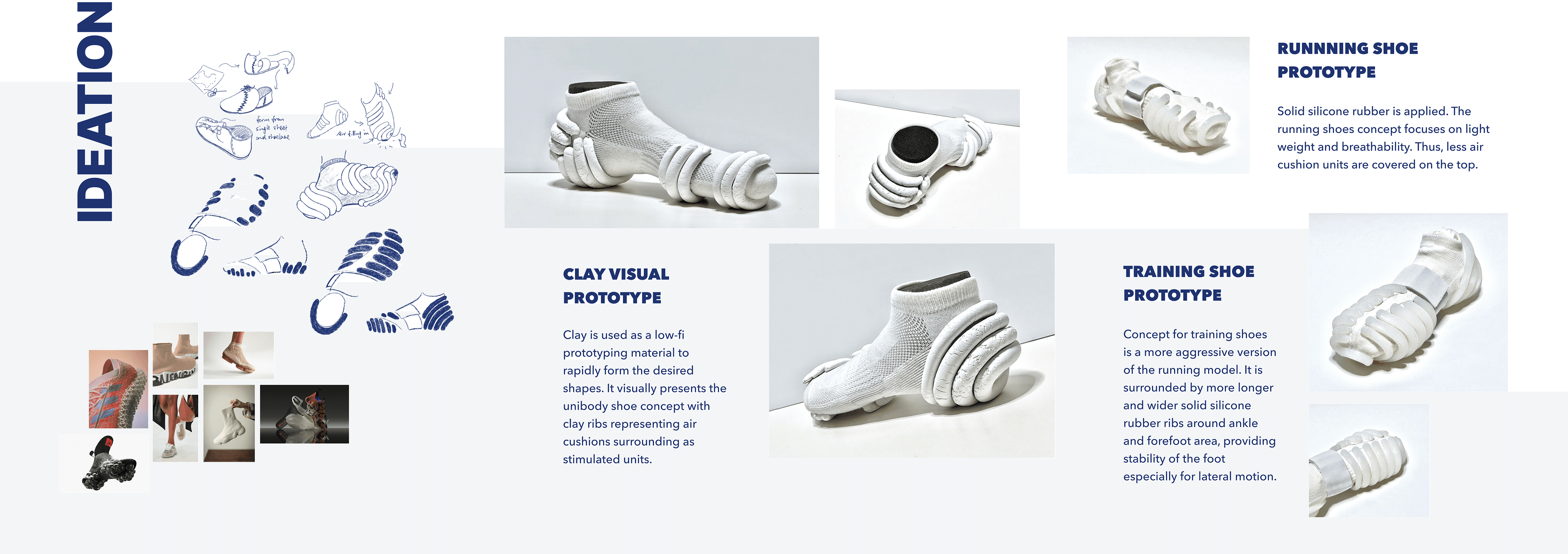

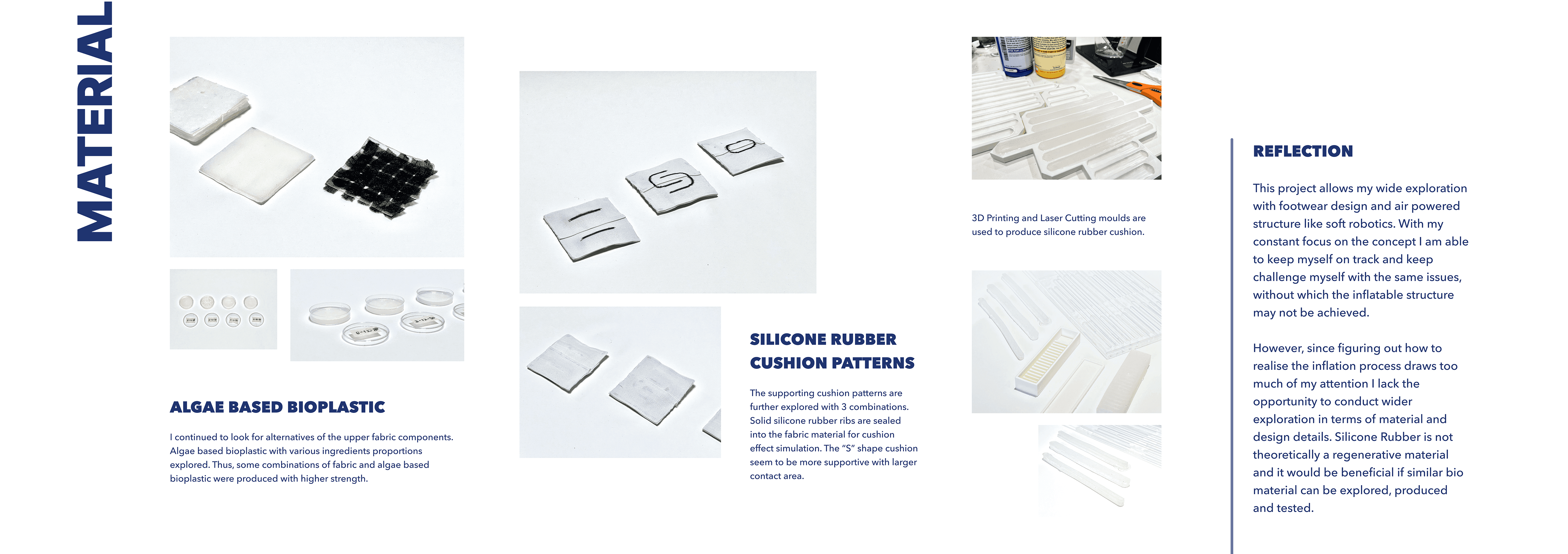

To develop the inflatable structure, I considered factors such as weight distribution, structure, shape, form, and materials. I experimented with soft robotics and iterated silicone rubber moulds to create the optimal cushion units.

AirForm

2023

Footwear Concept. Soft Robotics.

Individual Project

SuperGreen, Innovation Design Engineering (IC x RCA)

AirFORM aims to transform a single shoe into multiple styles through its form transformation ability, using an inflatable structure for adaptability. This reduces the need for multiple shoes, promoting sustainability. By activating specific air cushion units on the shoe’s surface, it inflates designated areas to achieve the desired shape for various shoe types.

Context

The majority of sneakers are made from plastics or similar materials, which generate significant carbon dioxide emissions. Typically, people wear different sports shoes for different activities, often storing those that are less frequently used. What if we could reduce our shoe collection and instead have one versatile shoe that adapts to various needs?

Concept

With the goal of transforming one shoe into multiple styles, I introduce AirForm, a footwear concept that uses air and inflatable mechanisms to create adaptive and regenerative structures. Equipped with individual cushion units connected to an air pump, the shoe’s form can be adjusted to any desired shape, allowing it to serve as various types of shoes.

Process

To develop the inflatable structure, I considered factors such as weight distribution, structure, shape, form, and materials. I experimented with soft robotics and iterated silicone rubber moulds to create the optimal cushion units.

AirForm

2023

Footwear Concept. Soft Robotics.

Individual Project

SuperGreen, Innovation Design Engineering (IC x RCA)

AirFORM aims to transform a single shoe into multiple styles through its form transformation ability, using an inflatable structure for adaptability. This reduces the need for multiple shoes, promoting sustainability. By activating specific air cushion units on the shoe’s surface, it inflates designated areas to achieve the desired shape for various shoe types.

Context

The majority of sneakers are made from plastics or similar materials, which generate significant carbon dioxide emissions. Typically, people wear different sports shoes for different activities, often storing those that are less frequently used. What if we could reduce our shoe collection and instead have one versatile shoe that adapts to various needs?

Concept

With the goal of transforming one shoe into multiple styles, I introduce AirForm, a footwear concept that uses air and inflatable mechanisms to create adaptive and regenerative structures. Equipped with individual cushion units connected to an air pump, the shoe’s form can be adjusted to any desired shape, allowing it to serve as various types of shoes.

Process

To develop the inflatable structure, I considered factors such as weight distribution, structure, shape, form, and materials. I experimented with soft robotics and iterated silicone rubber moulds to create the optimal cushion units.